Customization for Technical Requirements:

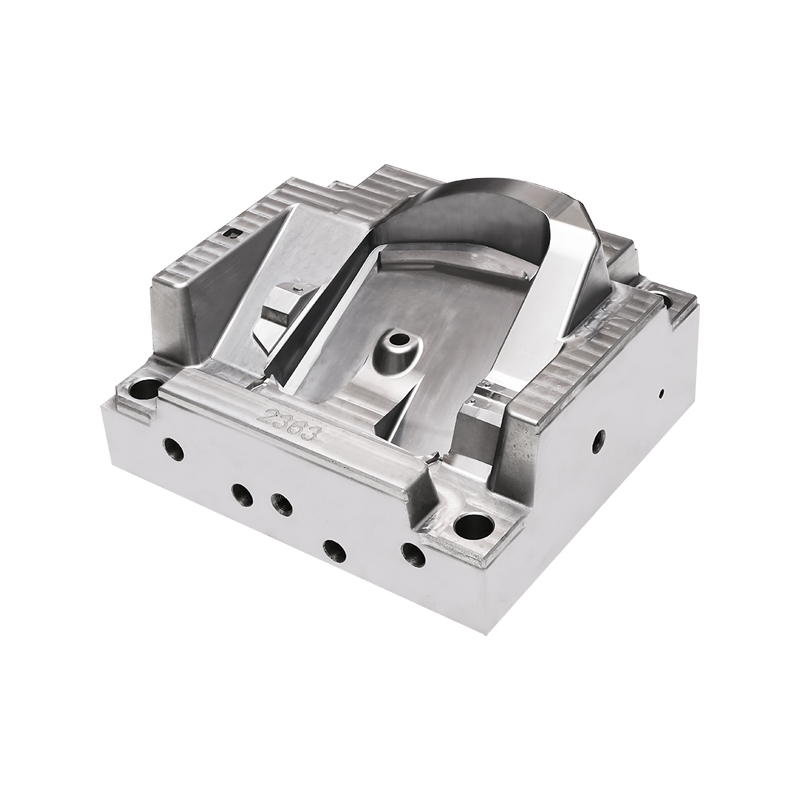

Our High Precision Auto Lamp Frame Mould is designed with a keen understanding of the technical requirements associated with injection molding for car lamps. We recognize the importance of customization in meeting specific industry needs, ensuring that the molds are adept at handling intricate designs and complex geometries. By offering customization options, we empower our clients to achieve seamless integration with their production processes, resulting in enhanced efficiency and productivity.

Materials and Process Considerations:

The success of injection molding lies in the harmonious blend of product process requirements and material characteristics. Our molds are engineered to withstand high pressure and temperature conditions, ensuring the production of injection-molded products with good hardness. The careful consideration of material properties, such as low viscosity, guarantees the smooth and efficient molding of intricate auto lamp frames.

Reliability and Consistency:

One of the key advantages of our High Precision Auto Lamp Frame Mould is the unwavering reliability and consistency it offers. Precision engineering and rigorous quality control measures are implemented throughout the manufacturing process, ensuring that each mold meets high standards. The result is a reliable tool that consistently produces auto lamp frames with precision and accuracy.

Enhanced Production Efficiency:

By integrating our High Precision Auto Lamp Frame Mould into the manufacturing process, clients experience a notable enhancement in production efficiency. Molds are optimized to streamline production processes, reduce downtime, and increase throughput. This efficiency translates into tangible benefits for our clients, contributing to overall cost-effectiveness.

Cost-Effective Solutions:

We understand the economic realities of the automotive industry, and our commitment to providing cost-effective solutions is evident in the design and production of our molds. The durability and longevity of our molds contribute to a lower total cost of ownership, making them a judicious investment for manufacturers looking to optimize their production processes.

Adherence to Industry Standards:

Our High Precision Auto Lamp Frame Mould complies with stringent industry standards, ensuring that clients receive a product that not only meets their specific requirements but also aligns with the regulatory guidelines of the automotive sector. This adherence to standards underscores our commitment to delivering molds that prioritize safety, quality, and performance.

Collaborative Approach:

Our team of experienced engineers and designers actively engages with customers to gain insights into their unique challenges and requirements. This collaborative approach enables us to fine-tune our molds to align seamlessly with the goals and objectives of our clients.

In conclusion, our High Precision Auto Lamp Frame Mould stands as a testament to our dedication to providing innovative solutions for the automotive industry. As a reliable partner in manufacturing, we continue to push the boundaries of what is achievable, ensuring that our clients benefit from solutions that elevate their production capabilities.