Key Features and Functionality:

Parabolic Curved Surface Design:

The fundamental design principle behind the Auto Lamp BMC Reflector Injection Mould is the implementation of a parabolic curved surface. This design choice is not merely aesthetic but has a profound impact on light collection efficiency. By adopting a parabolic shape, the reflector reduces light loss, ensuring that an improved amount of light is directed toward the desired target, whether it be the road ahead or the surrounding environment.

Optimized Light Distribution:

The reflective bowl's parabolic design not only reduces light loss but also optimizes the distribution of light. This ensures a uniform spread of illumination, reducing glare and enhancing the overall visual experience for drivers. The result is a well-illuminated road surface with minimal shadows and dark spots, promoting safer driving conditions during both day and night.

Durable BMC Material:

The Auto Lamp BMC Reflector Injection Mould is crafted from high-quality Bulk Molding Compound (BMC) material. This choice of material offers exceptional durability and resistance to environmental factors such as heat, moisture, and UV radiation. The robust nature of BMC ensures a prolonged lifespan for the reflective bowl, making it a reliable component in automotive lighting systems.

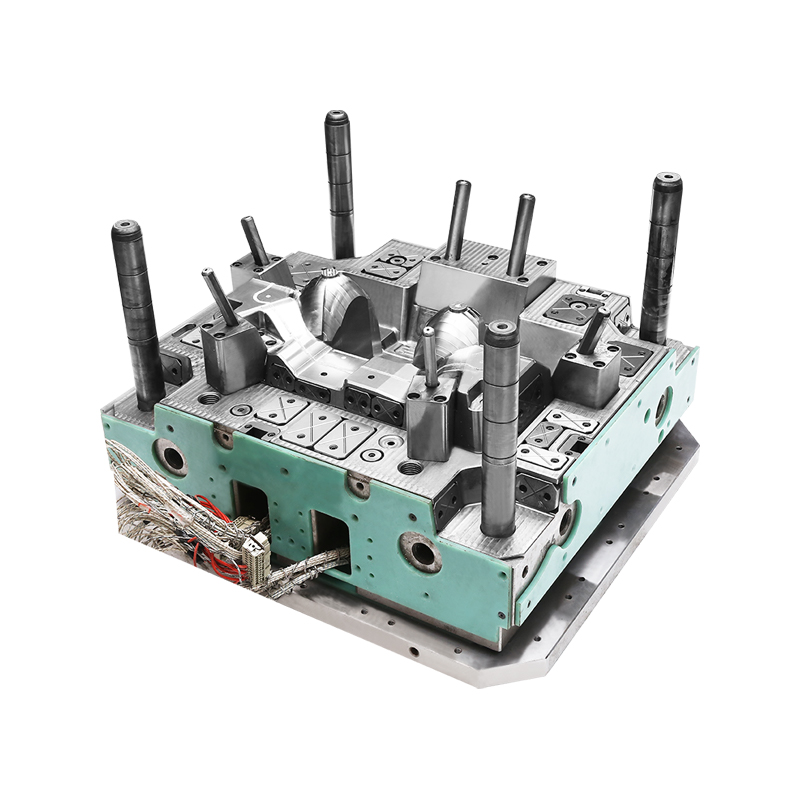

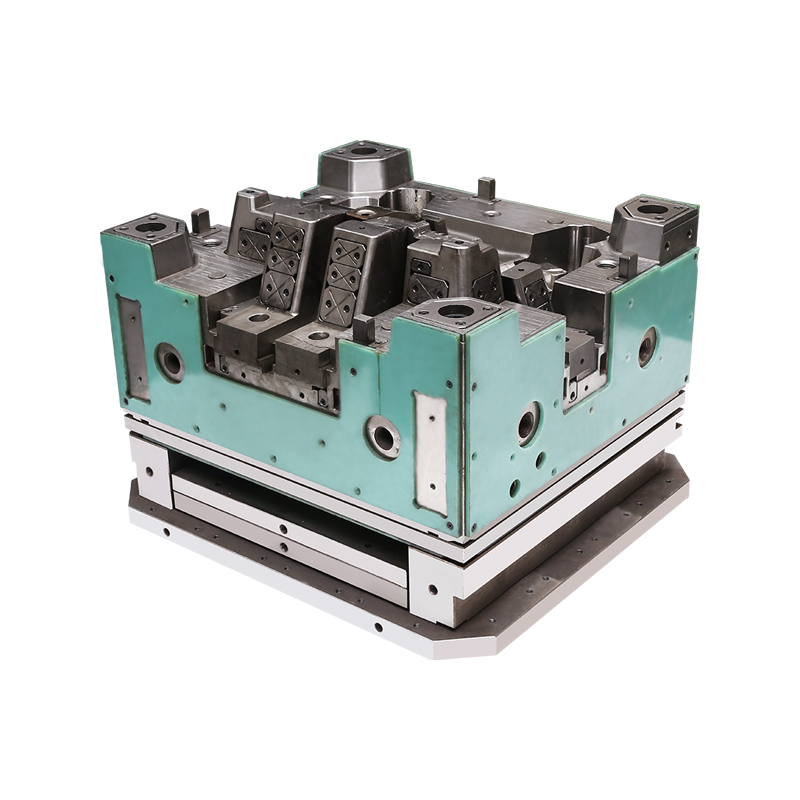

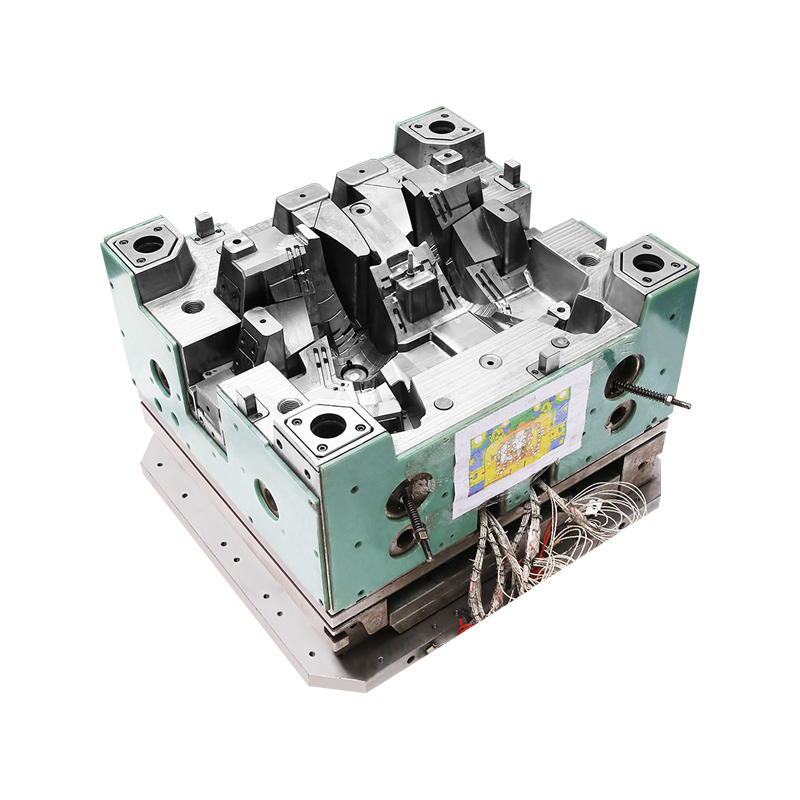

Precision Injection Molding:

The manufacturing process of this reflector involves precision injection molding techniques. This ensures a consistent and accurate replication of the parabolic design in every unit produced. Precision molding also contributes to the overall structural integrity of the reflective bowl, guaranteeing reliable performance under various operating conditions.

Compatibility with Different Light Sources:

The Auto Lamp BMC Reflector Injection Mould is designed to be versatile, accommodating various types of light sources commonly used in automotive lighting. Whether it is halogen, LED, or other emerging technologies, this reflective bowl is engineered to maximize the performance of different light systems, providing flexibility for automotive manufacturers and designers.

Ease of Integration:

Integrating the Auto Lamp BMC Reflector Injection Mould into existing automotive lighting systems is a seamless process. The design allows for easy installation, reducing assembly time and costs for manufacturers. This ease of integration ensures that the reflective bowl can be adopted without significant modifications to existing lamp designs, making it a practical and cost-effective solution.

In conclusion, the Auto Lamp BMC Reflector Injection Mould is a product that embodies precision, efficiency, and reliability in the realm of automotive lighting. Its parabolic curved surface design, coupled with the use of durable BMC material and precision injection molding, positions it as a key component in optimizing light collection for automotive lamps. As the automotive industry continues to evolve, this reflective bowl stands as a testament to the importance of thoughtful design and engineering in enhancing safety and performance on the road.